MECHANICAL SIZER

The machine is designed to grade fruit according to diameter.

Its structure consists of a solid 30/10 press-bending plate and 30/10 – 40/10 pipes treated with tarred rust preventer and semisynthetic paint.

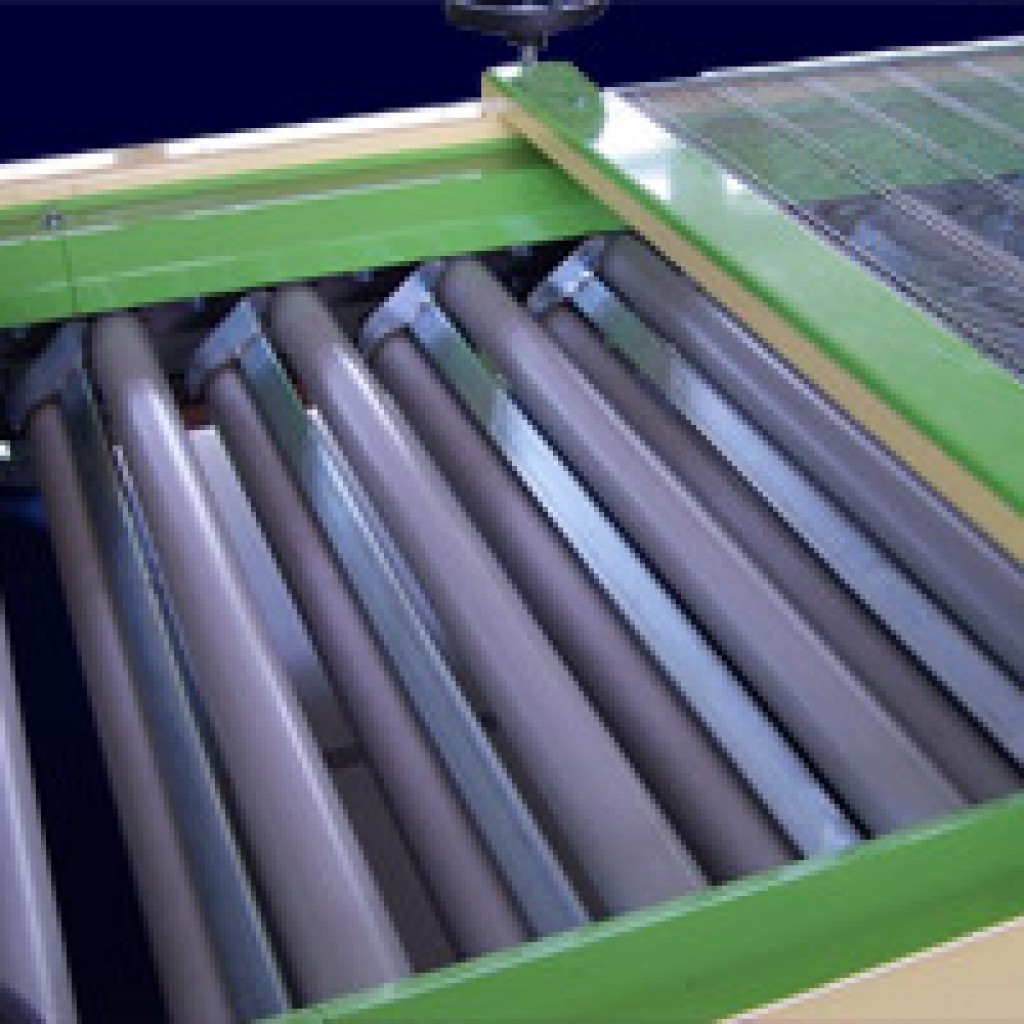

Grading is done on pairs of tilt rollers which space out as they advance dropping fruits down into belts beneath. Small-sized fruits drop into the first belt while large-sized fruits drop into the last exit belt.

Grading is adjustable by means of side handwheels in order to meet the client’s needs.

Rollers rotation (electronically controlled by a speed-adjustable gearmotor) enables the fruits arrangement on the right grading side whether they have an elongated (for ex. lemons) or spherical (for ex. oranges) or flattened shape (for ex. mandarins), ensuring an excellent grading result.

Steel rollers are inserted in a soft PVC sheath with a thickness of 30/10. Rollers are closed sideways between two steel hexagonal-shaped hubs with the hollow for the bearings (protected against dust and water). The through shaft is hooked to the hollow pins feed chain with bolts, while the die-cast aluminium tilt brackets with assembled brasses are inserted between the roller hooked to the chain and the tilt roller.

Driving is given by a chain with pins inserted into toothed pads housed at the ends of the rollers. The whole is connected to a chain above which determines the rotation of the pair of rollers.

Machine feeding through a 2 HP speed controller.

Rollers rotation through VARSPEEDY managed by a 3 HP electronic card (inverter).